Part I

Introduction

Introduction

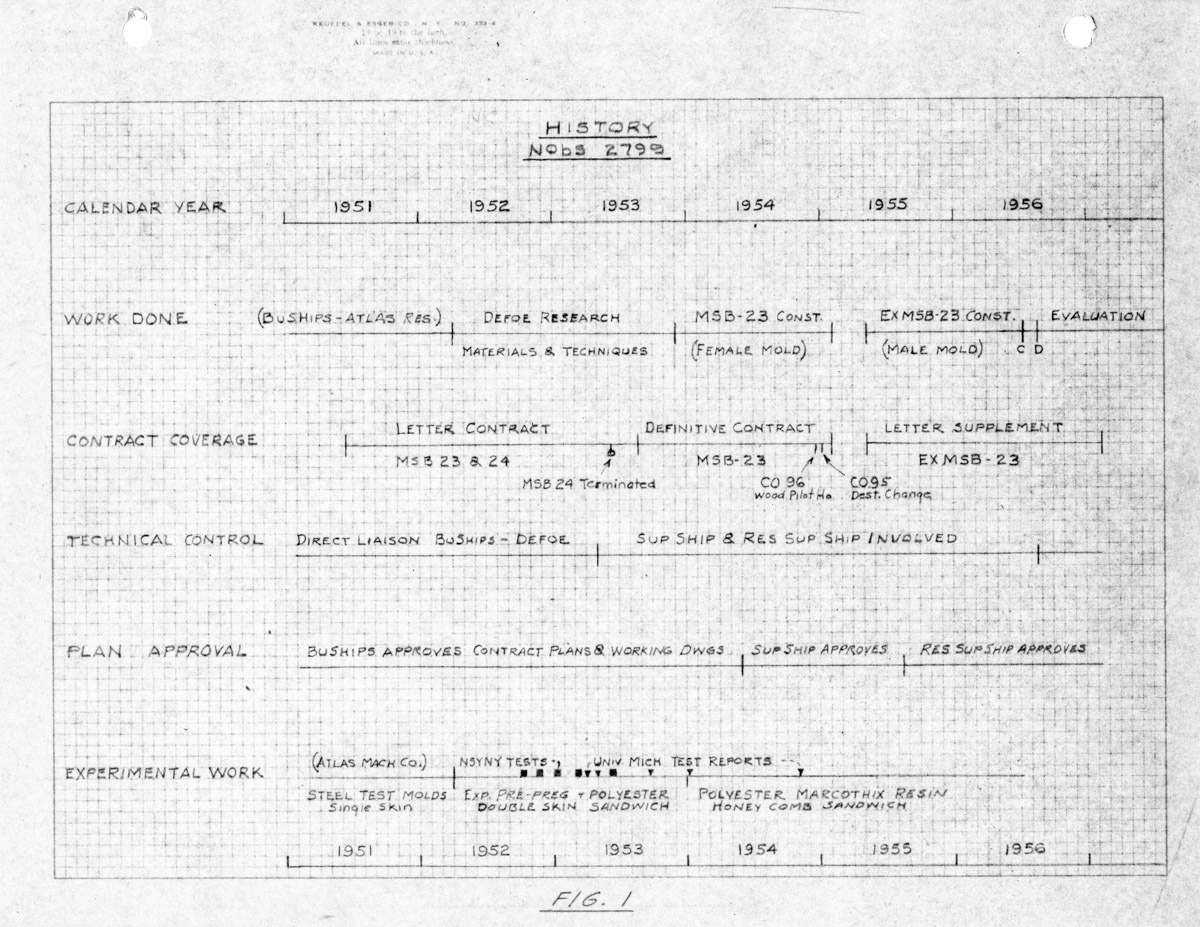

History of NObs-2799

This contract with the Defoe Shipbuilding Company originated as a letter contract dated 14 June 1951 which covered basic research, design, and construction of two (2) complete all-plastic 57' minesweeping boats of the MSB5 class, MSB 23 and 24. John Trumpy contract plans and working drawings for the wooden MSB5 class were provided Defoe for guidance. The MSB 23 and 24 were to be identical to the MSB5 in all respects except that the hulls were to be of reinforced plastic construction instead of wood. It was recognized that, while hull lines could be duplicated with minor modifications, all structural details, including those of the hull shell itself, would require careful redesign to take full advantage of the reinforced plastic medium and to allow for its shortcomings. Also, because a monolithic reinforced plastic hull of this size had never been designed and built before, and because design data on the behavior of reinforced plastic laminates for marine use were lacking, it was recognized that an extensive investigation of the available laminating materials would be required before final design details could be fixed. It was further recognized that the only way to determine the suitability of a reinforced plastic prototype of this size would be to build one and evaluate it in operation.

The letter contract dated 14 June 1951 stated that the preparation of contract and detail plans and specifications was to be based on a circular of requirements and a midship section drawing furnished to Defoe by the Bureau of Ships. The Bureau prior to that time had awarded a contract to the Atlas Machine and Iron Works, Arlington, Va.. This contract covered basic research and development work and the actual fabrication of test molds and full size hull sections of the MSB5 class. The results of this work were to have been incorporated in the circular of requirements and midship section and were to cover particularly the plastic design requirements. The work being done by Atlas Machine and Iron Works was principally directed toward utilizing the Marco method to mold a single skin hull with integral transverse framing. This project was never carried to its originally intended completion because, as is outlined later in this report, it became evident that the possibility of successfully molding an object as large and complicated as a 57 foot boat with integral transverse framing was remote, if not impossible. Therefore, in June of 1952 Defoe was informed that the circular of requirements and midship section drawing would not be furnished by the Bureau. The project as originally contemplated at the time of the letter contract was that the proven construction method would be developed by the Atlas contract and that Defoe would utilize this method. This, however, was not the case and at the termination of the Atlas contract, full responsibility of all phases of design, construction method, etc., was placed upon Defoe.

In June of 1953, MSB 24 was cancelled, and in August the letter contract was replaced by a definitive contract which considered only MSB23. The definitive contract provided for delivering a self-propelled plastic hull to the Navy for evaluation, and then, if the vessel proved to be satisfactory, to return it to the contractor's yard for completion as an operational minesweeping boat. The bulk of basic research was considered complete in November 1953 and the construction of the molds for the hull began. Two molds had to be constructed: one a male plug mold of wood and plaster, the other, a female mold of reinforced plastic and steel. The male mold was used only to build the female. The hull of the vessel was laid up inside the female mold. When about 2/3 complete, the partially completed hull shell and female mold were destroyed by fire.

Because a large number of prefabricated components were undamaged and no centrally procured or government furnished ship's equipment was destroyed, the question of whether to abandon the project or to reconstruct the vessel had to be considered. All work was stopped for a period of 3 months while Defoe and the Bureau studied the problem. The Navy still needed a large reinforced plastic vessel to evaluate, but it did not need another operational minesweeper of this class since the MSB construction program was complete. It was decided to strike MSB 23 from the list of naval vessels, delete all minesweeping, degaussing, communication, and navigation installations, substitute equivalent ballast, and deck over the reel well; in short, retain only those installations necessary to permit the vessel to operate as a self-propelled work boat during the evaluation period. Defoe convinced the Bureau that such a simplified vessel could be completed using a new construction method and within moneys still remaining in the contract. A supplemental ceiling price agreement was executed on 3 May 1956 and reconstruction was authorized.

The second vessel, carried as an item of Bureau of Ships equipment, was designated ExMSB-23. This time the hull shell and keel were laid up on a single wooden male mold in the upside down position, the whole assembly turned over, the mold removed, and the vessel completed. To employ this new molding process, some redesign was required, but the new method proved to be so much more rapid and satisfactory that in 14 months the vessel was ready for delivery. It was delivered to Navy Mine Defense Laboratory, Panama City, Florida on 5 July 1956 where it is presently being evaluated.

The following sections of this report develop details in the history of this project which are briefed here for general orientation.

Purpose

The purpose of this report is to present to the Bureau of Ships a resume of experience and findings by the Defoe Shipbuilding Company covering basic research, design, and construction of the largest monolithic-hull, reinforced plastic vessel constructed to date, and to present it in such a way that it can be quickly grasped, evaluated, and used in the planning of bigger and better reinforced plastic vessels for the fleet.

Scope

The report covers the whole period of the contract and is basically technical. It does not include a complete cost analysis, and does not deal with legal aspects. The findings of basic research in testing reinforced plastic materials and in developing construction processes are presented; design considerations are discussed; construction history and techniques are described and illustrated; and problems encountered and solved are individually discussed. Finally, some conclusions are drawn which may have application to planning of future projects of this kind. A fairly complete man-hour and completion-rate study covering reinforced plastic work is separately transmitted as an enclosure to the letter of transmittal along with revised specifications and a complete booklet of photographs which, if appended, would make the report too voluminous.