Part III

Tests, Chronological Sequence

Tests, Chronological Sequence

Since technical information and design data applicable to the design and construction of a large plastic boat were almost non-existant, and the specific materials themselves undetermined, many reinforced plastic panels were fabricated in an effort to determine the suitability of materials then available. Earliest panels were made principally so that familiarity with the handling characteristics of the materials could be gained. Soon, however, panels were made for testing in comparison with other more familiar materials and to gain knowledge of the relative values and properties of various components and panel structures.

In addition to the tests made by the Defoe Shipbuilding Company, other tests were conducted in connection with this specific project by the Dow Chemical Company, the University of Michigan, and the New York Naval Shipyard. Results of tests by Forest Products Laboratory of Madison, Wisconsin and others, while not specifically a part of this project, were often pertinent and very helpful.

Many test layups were made in addition to those listed, in an effort to determine feasibility of various fabrication techniques and to familiarize layup personnel with problems likely to be encountered. These are too numerous to describe.

The test programs discussed below were primarily directed toward arriving at a hull shell design with optimum strength, weight, rigidity, watertightness, durability, and economy. They are taken up in approximately chronological order and reflect the changes in concept brought about through the availability of newer and better materials.

3" x 16" Sandwich Panel Tests (Summer 1952)

Object -- In order to gain some idea of the behavior of the materials at hand, small sandwich panels 3" wide and 16" long were fabricated, using pre-impregnated glass cloths and various core materials, including:

(a) Western Products glass honeycomb, 1/4" cell size, phenolic impregnated

(b) Chrysler paper honeycomb, untreated

(c) Dow styrofoam, expanded unicellular polystyrene

(d) Lincoln paper honeycomb, polyester impregnated and untreated.

Core thickness varied between 1/2" and 1-1/2". The pre-impregnated glass cloth was furnished by Fabricon Products, Inc., of River Rouge, Michigan. Panels were oven cured under vacuum bag pressure at temperatures ranging from 175°F. to 230°F.

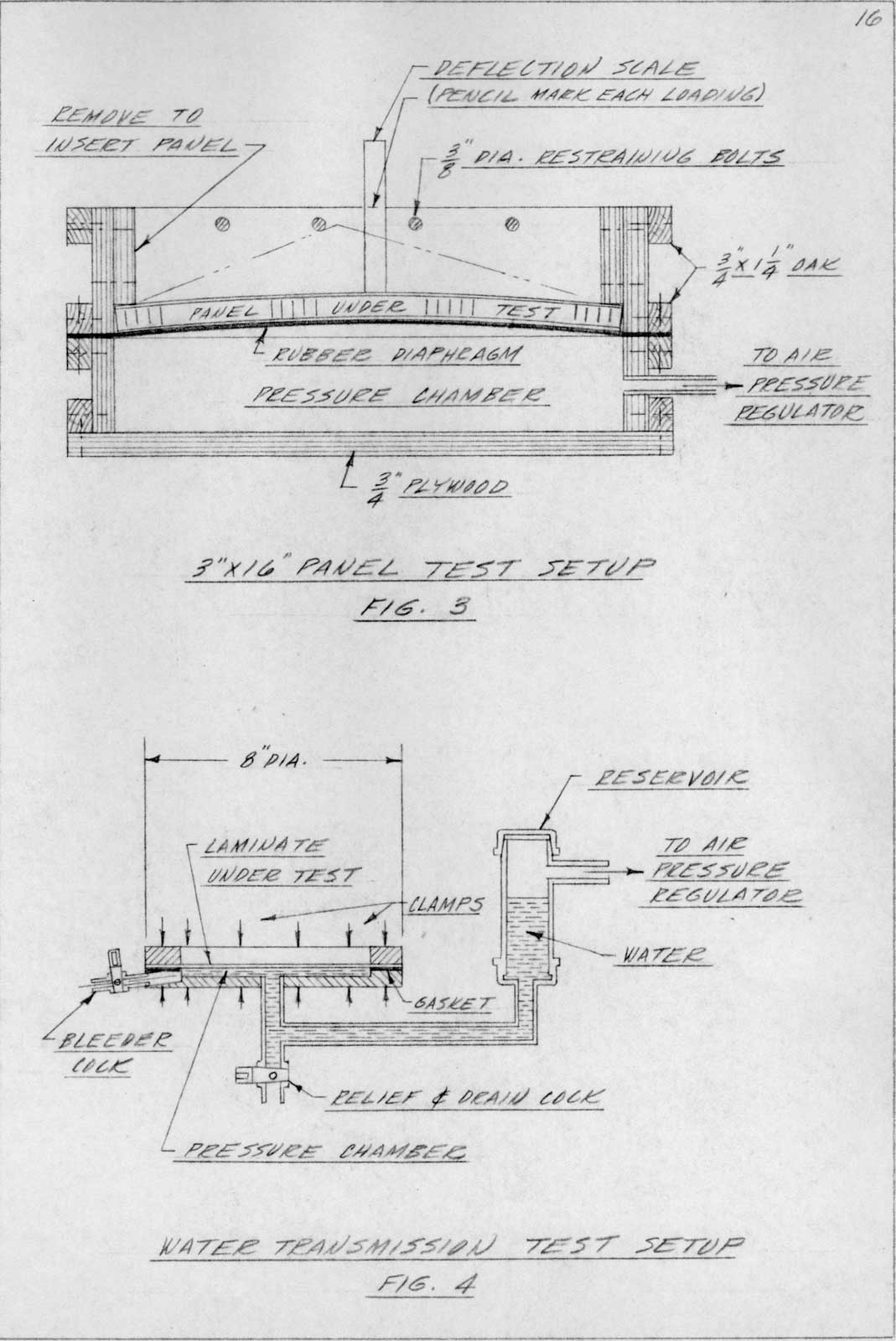

Method -- These panels were tested as simple beams in a test box using a rubber diaphragm and regulated air pressure to apply uniformly distributed loadings. See Fig. 3. After testing, portions of the panels were checked for impact resistance with a ball-pein hammer.

Results -- Load-deflection curves were not plotted, but deflection at 6 PSI was recorded for each panel as well as the pressure at failure. This material is included in Appendix B, page 102. Visual checks were made to ascertain impact damage.

Conclusions -- Certain conclusions were made as a result of these early tests among which were:

(a) Glass honeycombs tested were excessively brittle under impact and tended to shatter in the area of the blow.

(b) Bond strength between pre-preg laminates and styrofoam was poor. (Fabricon pre-preg resins were specially compounded for use with styrofoam because of solubility of styrofoam in styrene, a component of most common polyester resins). Low softening temperature of styrofoam (around 180°F.) required low curing temperatures which contributed to indifferent laminate quality.

(c) The 3"x16" panel size was too small for core thicknesses over 1/2", since bond shear failures starting at the ends of the thicker panels were general.

(d) Air pressure as a loading medium was found to be unsatisfactory.

A larger test box using a hydraulically loaded diaphragm was devised for use during the next phase of the program.

Water Transmission Tests (Sept. 1952 - Feb. 1953)

Pre-Preg Laminates -- A short series of tests was made to determine the extent to which porosity of pre-preg laminates contributed to water transmission.

Laminate samples 8" in diameter were clamped in a jig and subjected on one side to water under pressure. Regulated air was used to control the pressure of the water against the laminate. See Fig. 4, page 16. Water penetration was evidenced by droplets showing on the upper surface of the laminate.

It was found that in any laminate of Fabricon pre-preg cured under bag pressure and consisting of less than four plies, excessive water penetration was general.

Entrapped air bubbles being an unavoidable concomitant of pre-preg laminates, it was evident that four plies or more were necessary in a laminate in order to provide minimum water tightness, with a distinct possibility of void continuity existing on occasion in laminates of six plies or more.

Marcothix Laminates -- Wet layups using thixotropic resins proved far superior to pre-preg laminates tested. An average two-ply laminate using 1044 cloth would provide adequate water tightness.

5" x 20" Sandwich Panel Tests (Oct. 1952 - May 1953)

Object -- These tests were made in an effort to determine whether behavior of materials was consistent over a considerable number of panels and to develop the best distribution of materials as to number of plies and core thickness. Strength comparisons were made between plastic sandwich panels and various wood panels and the effect of water immersion on panel strength was briefly investigated. Other core materials were tried in the early stages of this phase, including Douglas paper honeycomb and U. S. Plywood 4 oz. cotton honeycomb. Tests made by the Forest Products Laboratory at Madison, Wisconsin showed that the cotton honeycomb was far superior to paper honeycomb in wet strength retention, a property of considerable importance in marine applications. The higher cost of the cotton core material was considered justified in view of this consideration, and it was ultimately selected as the best available core material. Also available was a honeycomb made of aluminum foil. This material was not considered because of possible magnetic field complications. Practically all 5" x 20" panels were made with cotton honeycomb and core thicknesses ranged from 1/2" to 2". Panels were fabricated using pre-preg materials supplied by Fabricon Products, Inc.; Cordo Molding Products, Inc.; and Sun Chemical Corporation. Curing was accomplished under vacuum bag pressure and at temperatures to 250°F.

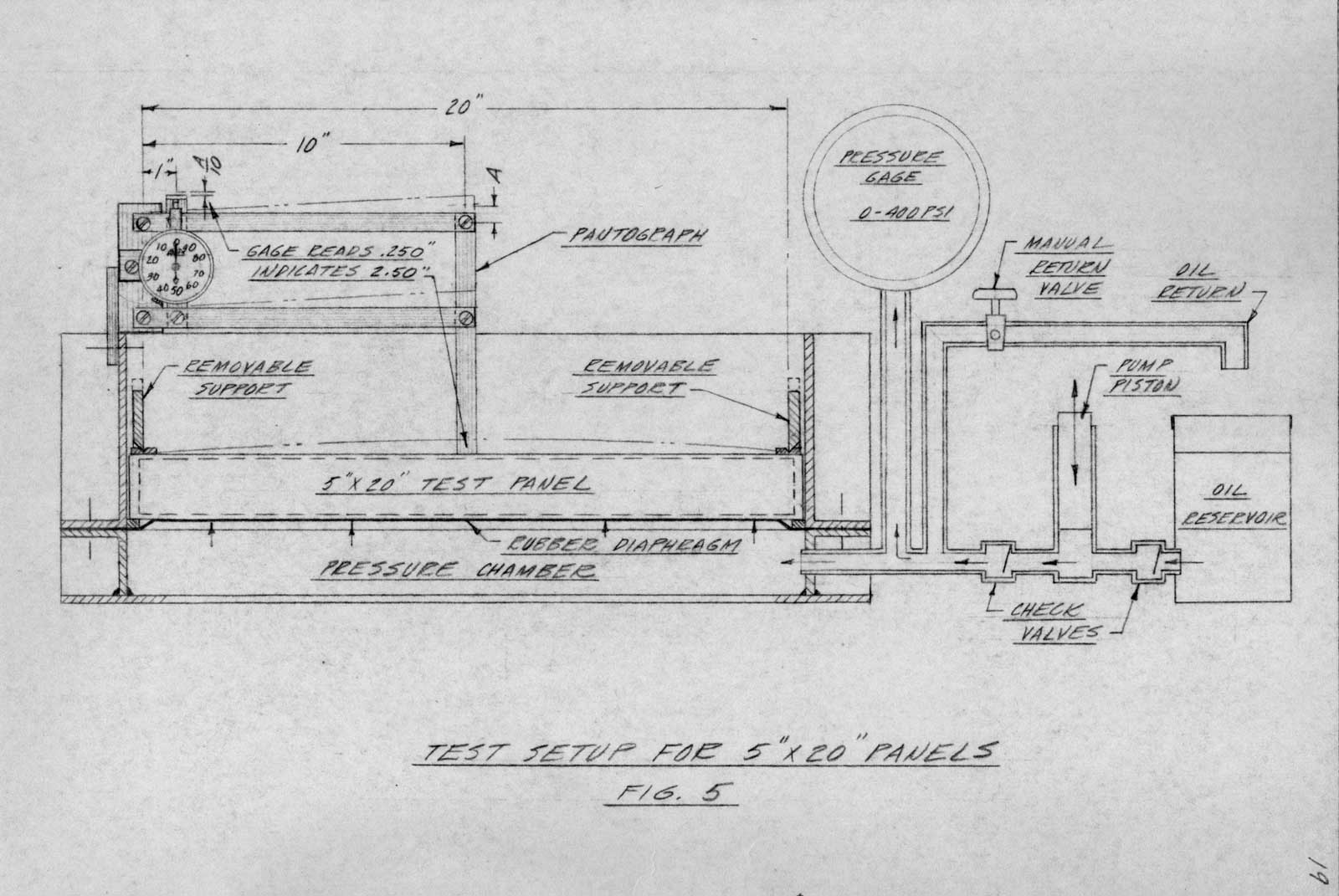

Method -- 5" x 20" panels were tested as simple beams in a steel test box utilizing a hydraulically loaded rubber diaphragm to produce distributed loadings. Deflections were measured at mid-span by means of a dial gauge coupled to a pantograph arrangement giving a ratio of 1 to 10 and reading deflections up to 2.5 inches to the nearest .01 inch. See Fig. 5, page 19.

Early tests indicated that this panel size was still too small for use with core thicknesses over 1", if panel ends and edges were not reinforced, so the majority of subsequent panels were made with sealed edges and reinforced ends. This cut down the incidence of bond shear failures and increased the likelihood of rupture in the laminates.

Results -- Load-deflection curves were plotted using the same scale throughout to aid visual comparison. See Appendix B, pages 103-114.

Conclusions -- At the completion of this test phase, it was concluded that panel uniformity was satisfactory and that 2" was about the maximum desirable core thickness. Greater core thicknesses were possible, but weight added in the form of bossing for thru-bolts would offset other gains.

Inspection of the load-deflection curves also shows the relative effects on stiffness of increasing core thickness and increasing skin thickness. Increasing core thickness rather than skin thickness has the additional advantage that the moment of inertia may be increased with less added weight.

Water immersion tests were not extensive enough to be conclusive, but load-deflection curves are included in Appendix B, page 113.

Dow Chemical Co. Tests (Dec. 1952 and Feb. 1953)

On two occasions, tests were performed by the Dow Chemical Company of Midland, Michigan. The first tests were made to determine the tensile properties of Fabricon pre-preg laminates (150-164 cloth) and the compressive strength of U. S. Plywood cotton honeycomb. Later tests were made to determine tensile properties of Marcothix laminates (12 plies #1000 cloth).

Tensile tests were conducted on a Baldwin-Southwark Machine using the 2000 lb. load scale and a crosshead rate of 0.05 inch per minute.

Compressive tests were conducted on the same machine using a crosshead rate of 0.025 inch per minute.

Results are listed below:

1. Average of 9 to 10 determinations, pre-pregs

Tensile strength, PSI 19,925

Elongation, % 1.26

Modulus in Tension, PSI 2,163,000

2. Average of 9 to 10 determinations, honeycomb

Compressive strength, PSI 579

Compression, % 2.1

Modulus in compression, PSI 35,175

3. Average of 11 determinations, Marcothix

Tensile strength, PSI 23,070

Elongation, % 1.70

Modulus in tension, PSI x 10⁶ 2.07

University of Michigan Tests

Several test programs were performed at the Materials Testing Laboratories of the University of Michigan Engineering School. These tests were covered in five reports, copies of which are on file at the Bureau of Ships. Properties covered in each report are listed below.

First Report (March 1953)

Behavior of Fabricon pre-preg laminates in flexure, compression, fatigue, shear, torsion, impact, bearing capacity and thermal characteristics such as thermal conductivity and specific heat.

Second Report (April 1953)

Behavior of Marcothix laminates in flexure, compression, fatigue, torsion, impact and bearing.

Third Report (September 1953)

Behavior of Marcothix laminates of various combinations of cloth and mat in flexure, compression, tension, impact, bearing capacity, and moisture absorption. Also the re-testing of Marcothix-cloth laminates after prolonged immersion in water.

Fourth Report (January 1954)

a. Moisture effects; water absorption, compressive strength, modulus of elasticity.

b. Flexure of honeycomb cored panels.

c. Compressive, tensile and flexural strength of plate material from cored panels.

Fifth Report (November 1954)

a. Flexure tests of deck slab specimens

b. Compression tests of vermiculite-resin filler material

c. Secondary bond strengths

For methods, results and conclusions, see the appropriate report.

New York Naval Shipyard Tests (November 1952 - April 1954)

New York Naval Shipyard Project 4860-Q7 was undertaken to determine the structural properties of laminated plastic panels submitted by the Defoe Shipbuilding Co. and to compare results with a wooden panel of approximately equal weight, indicative of typical ship construction.

These panels were approximately 99" square overall including a wooden frame 4-3/8" wide, provided at the panel edges in order to provide the constraint required for the test. The resulting net dimensions of the test panels were 90" x 90". Four plastic panels were provided, the first three being of pre-preg materials and the fourth of Marcothix, 1044 cloth, and Bigelow Sanford mat. A fifth panel was provided for comparison and was of wood construction similar to the structure of the wood MSB-5 class vessel.

Each panel was clamped into a hydraulic loading device consisting of two square steel channel frames, upper and lower, designed to permit clamping a panel between them in order to obtain, as closely as practicable, the fixed end condition required at all four edges. The lower frame was designed with a hydraulic chamber, utilizing the full inside area of the frame which was open to the underside of the clamped panel.

A supply line tapped into one side of the hydraulic chamber provided a means for admitting water under pressure to the full underside of the panel. Dial gauges were located strategically over the panel surface in order to measure deflections with suitable accuracy at each applied load.

While none of the plastic panels tested were equivalent to the final plastic sandwich structure determined for MSB-23, all plastic panels proved superior to the wooden panel. The plastic panels were lighter in weight, showed greater rigidity and sustained appreciably higher ultimate loads. One curve sheet taken from the report shows comparative load-deflection curves at center gauge for panels DSC-1, 2, 3, 4W, and 5. See Appendix B, page 115.

Further details of the panels, test method and results may be found in the lab report Lab Project 4860-Q-7, Final Report, NS034-045, Sub Task 18, from which most of the above description was taken.

9" x 60" Panel Tests (June 1953 - April 1956)

Object -- Since both the 3" x 16" and the 5" x 20" panel sizes had proved too small for effective use as test panels when made with the thicker cores, a test assembly was built for testing sandwich panels 9" x 60" in size. This panel was used for all further testing at the contractor's plant.

Tests were made over a considerable period of time in an effort to determine the following:

(a) Optimum number of plies for inner and outer skins.

(b) Merits of various systems for bonding laminates to honeycomb.

(c) Relative values of flat bar and Z-bar longitudinal stiffeners.

(d) The effects on panel strength of secondary bonds and interrupted fabrication sequences.

(e) Relative panel strengths using different laminate reinforcements.

(f) Performance of new shipments of materials.

Method -- All panels were made with cores of cotton honeycomb 1-3/4" thick and neither ends nor edges of panels were reinforced.

These panels were tested in simple bending under a concentrated load at mid-span. Load was applied using a hydraulic ram equipped with a pressure gauge. The test setup is shown in photograph A9.

Load-deflection curves were plotted using total applied load which was obtained by multiplying gauge pressure by ram area. This was done because rams of different areas were used during the earlier and later parts of the program and it was desired to have all curves on the same scale for easier comparison.

Results -- Resulting curves are included in Appendix B, pages 116-142.

Conclusions -- Conclusions are listed below:

(a) The outer skin was fixed at 7 plies of style #1044 cloth and the inner skin at 4 plies.

(b) Using 1 ply of impregnated mat between honeycomb and cloth laminates yielded the best combination of high bond strength with ease and uniformity of application. The additional weight of the added mat and resin was accepted as necessary to produce consistent results. Other bonding methods tried and the reasons for their rejection are:

(1) Results of bonding laminates directly to core were extremely variable with too high an incidence of bond failures.

(2) Epoxy resins as bonding adhesives worked well, but their use would have been difficult to fit into the process.

(3) Resin-dipped cores bonded directly to face laminates showed little improvement over undipped cores.

(4) Application of resin and milled fibers between laminates and honeycomb showed some bond strength improvement but uniform application was difficult.

(c) Tests showed that Z-bar stiffeners were not enough superior to the simple flat bar webs to justify the additional effort and expense which their inclusion would entail.

(d) Discontinuities in the fabricating process did not significantly affect panel strength, a fact which simplified anticipated problems considerably.

(e) A number of panels using woven rovings were made and tested which showed significantly higher strengths than those using 1044 cloth. However, technical difficulties in the weaving of these materials made delivery in quantity of a uniform product impossible. For this reason the 1044 cloth was retained as the laminating reinforcement.

(f) The small number of quality assurance panels made showed close correlation with earlier test panels.